Please enter a keyword to search

a. General

All underground or enclosed trainways including elements of structure of the trainways, cross-passageways, doors, and walk surface designated for evacuation of passengers shall be constructed of non-combustible materials.

b. Fire resistance of elements of structure

The fire resistance of the elements of structure for the underground or enclosed trainway shall be at least 4 hrs.

c. PVC pipes, conduits, and fittings

Except as permitted in Cl.9.3.1f., exposed PVC pipes, PVC conduits and fittings are not allowed in the underground or enclosed trainway.

d. Vertical exit shafts and ventilation structures

The fire resistance of the elements of structure of remote vertical exit shafts and ventilation structures shall be at least 2 hrs. Test of fire resistance shall be in accordance with Cl.3.4.

e. Ancillary areas

Ancillary areas shall be separated from the trainway areas within underwater line sections (such as those under the sea, reservoir, river, or canal) by at least 3-hrs fire-resistant construction. Ancillary areas shall be separated from the trainway areas within underground line sections by at least 2-hr fire-resistant construction.

f. Cover board

Cover board or any protective material used to provide safety isolation from the contact traction power rail shall have a flame spread rating of at least Class 1 as specified in Cl.3.13.3 when tested in accordance with BS 476: Part 7.

a. Provision

Exits shall be provided from underground or enclosed trainways to a point of safety.

b. Exit staircases

Exit staircases shall be provided throughout the underground or enclosed trainways and spaced so that the distance between exit staircases is at most 760m. The staircase shall be enclosed and shall lead directly to the outdoors or to a safe refuge area. The minimum clear width of the staircase shall be 1m. Handrails shall be provided in accordance with Cl.2.2.10f.. The staircase shall be ventilated in accordance with Chapter 7.

Where underground or enclosed trainways are divided by at least 2-hr fire-rated walls or where trainways are in twin bores, such an arrangement shall be deemed to afford adequate protection for the passengers via cross passageways between the trainways and shall be permitted to be utilised in lieu of exit staircases to the surface. The following shall apply:

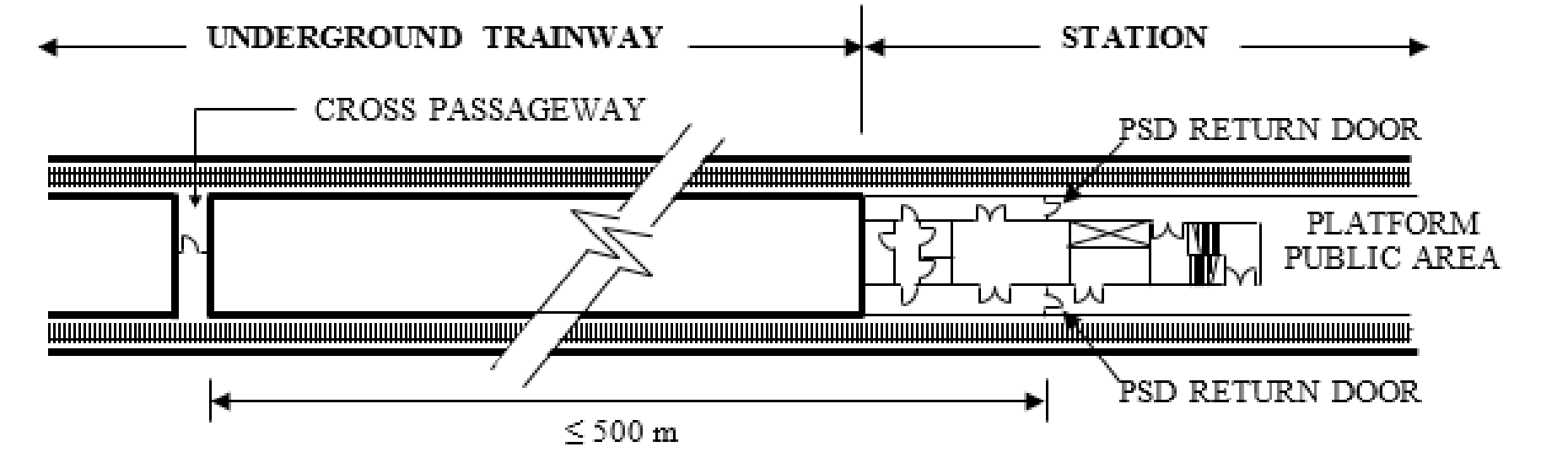

a. The distance between a cross passageway and an exit staircase or the platform public area shall be at most 500m. See Diagram 9.3.3a..

Diagram 9.3.3a.: Location of First Cross-passageway in Underground Trainways

b. Cross-passageways shall be at most 250m apart.

c. Opening in cross passageway with a minimum clear width of 1m shall be protected with a fire door assembly having a fire resistance of at least 2-hrs with a self-closing device.

d. A non-contaminated environment shall be provided in that portion of the trainway that is not involved in an emergency and that is being used for evacuation.

e. A ventilation system for the contaminated trainway shall be designed to control smoke in the vicinity of passengers.

f. A suitable method shall be provided for evacuating passengers in the uncontaminated trainway, for protecting passengers from on-coming traffic, and for evacuating the passengers to a nearby station or another exit.

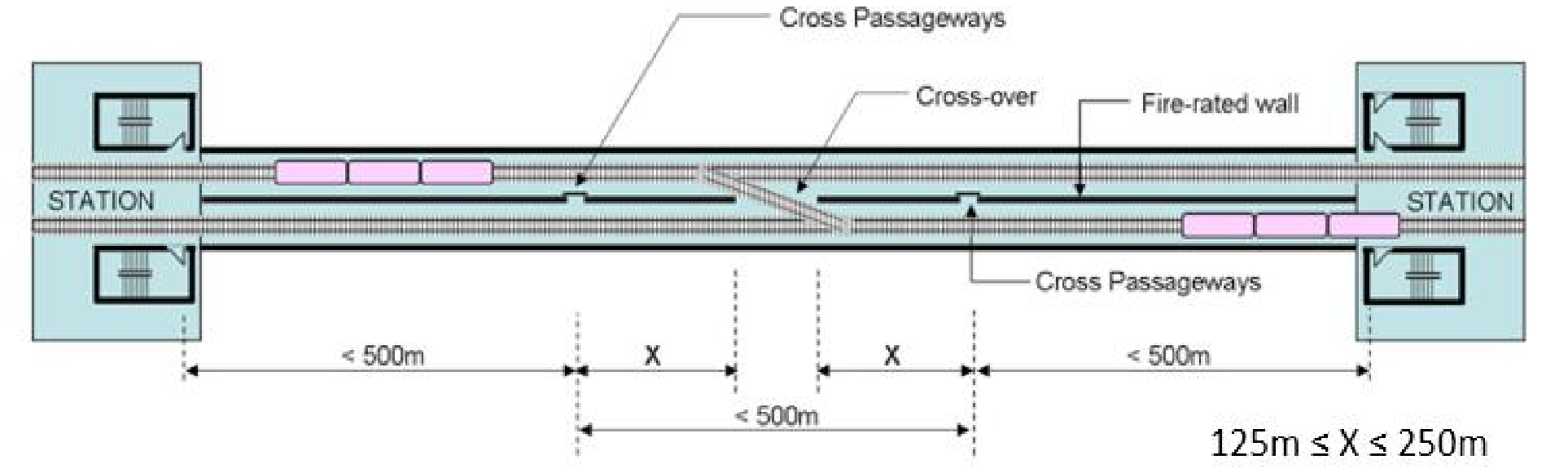

g. Where cross-over that breaks the fire separation between enclosed trainways is provided, the following conditions shall be complied with:

(1) The design of the emergency ventilation system shall also meet the requirements of Cl.9.3.11e.(1) for the scenario where train fire occurs at the cross-over.

(2) Distance between the cross-passageways at upstream and downstream of the cross-over shall be at most 500m apart.

(3) Distance between the cross-over and the nearest cross passageway shall be at least 125m and at most 250m. See Diagram 9.3.3g..

Diagram 9.3.3g.: Cross-over Between Enclosed Trainways

Doors to an exit shall open in the direction of exit travel except in the case of cross-passageway closures. Doors to the exit access in the trainways shall be provided with a self-closing device but no locking device shall be provided. The force required to open the doors fully when applied to the latch sided shall be as low as possible, not exceeding 220N. In addition, door and hardware shall be adequate to withstand the positive and negative pressures created by passing trains.

An effective emergency egress pathway of minimum 800mm width shall be provided. In areas with cross passageways, unobstructed access shall be provided to the cross passageways.

The walking surfaces of the emergency egress pathway shall have a non-slip design.

Where the trainway concreted track bed serves as emergency egress pathway, it shall be nominally level, and free of obstructions. Where signalling equipment is located along the emergency egress pathway, ramp, and platform shall be provided. The edges of the ramp and platform shall be painted with bright yellow paint to enhance its visibility.

a. General

Exit facilities shall be suitably identified and maintained to allow for their intended use.

b. Exit signs

Exit signs at exit staircases shall comply with the requirements as specified for stations in Cl.8.1.7, whereas non-maintained illuminated exit signs at cross-passageways shall be designed to be remotely controlled to support the evacuation strategy.

c. Signage

Signage shall be provided to assist emergency evacuation of passengers. The signs shall be reflective or illuminated.

d. Emergency lighting

Emergency lighting shall be provided to underground or enclosed trainways exceeding 15m in length. The illumination level at walking surfaces shall be at least 2.7 lux.

e. Emergency power supply

The emergency lighting shall be connected to an emergency power supply capable of maintaining the minimum illumination level for at least 2 hrs.

f. Fire resistant cables

Fire resistant cables of at least 2-hr rating shall be used.

a. Dry rising mains

Underground or enclosed trainways shall be provided with dry rising mains. The dry main system and its associated water supply, control, and testing requirements shall be installed in accordance with SS 575, except as herein modified:

(1) Dry rising main system shall be provided in accordance with Diagram 9.3.9a.(1) for the following areas:

(a) Each underground trainway located between two stations;

(b) Each underground or enclosed trainway between a station and the trainway portal; and

(c) Each underground or enclosed reception or test track.

.png?sfvrsn=a1596059_1)

Diagram 9.3.9a.(1): Dry Main System in Underground or Enclosed Trainway

(2) For over-run trainway, the dry rising main system can be served with only one breeching inlet at the station end.

(3) The nominal bore of the dry rising main shall be at least 150mm.

(4) The dry rising mains in the trainways need not be fire-rated.

(5) Landing valves shall be located at least 2m and at most 3m apart from exit staircases and cross passageways and shall be spaced at intervals at most 60m along the trainway.

(6) The first landing valve of the dry rising main after the breeching inlet shall be located at most 3m from the interface of the station box and the trainway. For the case of Cl.9.3.9a.(1)(b), the first landing valve after the breeching inlet shall be located at most 3m from the portal.

(7) Where gaskets are used in pipe joints for dry rising mains serving different trainways but located in common TV vent shaft and TVF fan room, the gaskets shall be suitable for use in an ambient atmosphere of 250°C.

(8) Breeching inlets

The breeching inlets shall be located within 18m from the fire engine accessway and be visible from the fire engine accessway. Breeching inlets shall be appropriately numbered and labelled as shown in Diagram 9.3.9a.(8).

.png?sfvrsn=c3a61295_1)

Diagram 9.3.9a.(8): Numbering and Labelling of Breeching Inlets for Underground or Enclosed Trainway Dry Rising Mains

(9) Standby fire hoses

Two standby fire hoses shall be provided at each of the following locations:

(a) Buffer area within 3m from the stair leading to the trainways. See Diagram 9.3.9a.(9)(a);

(b) Mid-tunnel exit staircase; and

(c) Underground or enclosed trainway portal. See Diagram 9.3.9a.(9)(c).

Standby fire hoses shall be provided in accordance with Cl.6.2.4 with the exception of Cl.6.2.4b..

(a).png?sfvrsn=2d2c12ad_1)

Diagram 9.3.9a.(9)(a): Location of Standby Hoses Outside Platform Public Area

(c).png?sfvrsn=3af17753_1)

Diagram 9.3.9a.(9)(c).: Location of Standby Hoses at Underground or Enclosed Trainway Portal

b. Automatic fire detection systems

Automatic fire detection systems shall be provided at designated locations in underground or enclosed trainways where trains are stabled during non-revenue hours. The guidance for selection of detectors is described in SS 645. The use of line type heat detectors is permissible.

a. Provision

Underground or enclosed trainways shall be provided with radio communication facilities capable of operating in the frequency band as allocated and approved by the authority having jurisdiction.

b. Fire resistant cables

Fire resistant cables complying with SS 299 shall be used for communication system equipment, except for the leaky co-axial (LCX) cables which are required to be fire retardant.

a. Provision

A mechanical emergency ventilation shall be provided in underground or enclosed trainways exceeding 300m.

b. Exemption

A mechanical emergency ventilation system is not required for underground or enclosed trainways at most 60m in length.

c. Engineering analysis

An engineering analysis is required for underground or enclosed trainways more than 60m but less than 300m in length to determine if a mechanical emergency ventilation is required. The analysis shall take into consideration all the factors that affect fire safety. A report of the analysis shall be submitted. If the engineering analysis is not carried out, then a mechanical ventilation system shall be provided.

d. Operation duration

The emergency ventilation system shall make provisions for the protection of people from fire and smoke during a fire in the underground or enclosed trainways and shall be designed to maintain the required air flow rates for at least 2-hrs.

e. System requirements

The emergency ventilation system shall:

(1) provide a tenable environment along the paths of egress in the incident and non-incident trainways;

(2) be able to achieve the critical velocity;

(3) be capable of reaching full operational mode within 120 secs or less; and

(4) address the maximum number of trains that could be between ventilation shafts during an emergency.

f. Design

The design shall encompass the following:

(1) The heat release rate from a vehicle and any other combustible materials (if permitted) in the trainways that could contribute to the fire load at the incident site, subject to the approval of the SCDF.

(2) The rate of fire growth.

(3) Station and trainway geometries.

(4) Fans, shafts, and devices for directing air.

(5) Predetermined procedures for initiating quick response from the OCC during fire.

g. Ventilation fan

The emergency ventilation system fans shall be capable of satisfying the emergency ventilation requirements in either the supply or exhaust mode. Emergency ventilation fan motors shall be designed to achieve their full operating speed in 30 secs or less from a stopped position when started across the line and in 60 secs or less for variable speed motors.

h. Fan rating and standby

Emergency ventilation fans, their motors, and all related components exposed to the exhaust airflow shall be capable of operating in an atmosphere of 250ºC for a minimum of 2 hrs. The emergency ventilation fans shall be provided such that in the event one of the fans in the operating system is not operational, the other fan(s) shall be capable of maintaining the system design.

i. Siting of fan starter and control devices

Local fan motor starters and related operating control devices shall be located as far away from the direct air stream of the fans. Thermal overload protective devices shall not be used on motor control of fans used for emergency ventilation.

j. Operation of non-essential fans

Fans not designed to function during fire shall shut down automatically upon activation of an emergency ventilation system unless it can be proven that the emergency air flow is not jeopardised or conflicted with.

k. Cables

Cables used for wiring the fans and the associated controls shall comply with Cl.5.2.2.

l. Emergency ventilation system control/ operation

Operation of the emergency ventilation system shall be initiated from the OCC. Local controls located in the PSC of the station, shall be provided and be allowed to control the emergency ventilation system only when the authority is delegated from the OCC to the station PSC.

m. Requirements for system devices

Devices of the emergency ventilation system such as dampers, louvres, silencers, etc., shall be capable of withstanding the repetitive and additive piston effect of moving trains and emergency air velocities. Such devices shall be of non-combustible, fire-resistant materials and be protected, to the greatest extent practical, against fire near the incident area.

n. Vent shafts

Vent shafts that penetrate the surface and that are used for intake and discharge in fire emergencies shall be designed to prevent recirculation of smoke into the station and trainway through air intake openings, station entrances and other surface openings.

A minimum 1m wide access stair from the ground level to the underground or enclosed trainway portal shall be provided. A gate of minimum 1m width shall be placed as close as possible to the portal to permit easy access to underground or enclosed trainway.

a. Provision

Motorised trolley shall be provided at each of the following location:

(1) Station platform level

(2) Mid tunnel exit staircase more than 380m from a station

(3) Trainway portal

b. Construction materials

Motorised trolley shall be constructed of non-combustible material and firmly hanged on wall. Accessories (i.e., batteries, battery chargers, ignition key, handle, and controller) shall be housed in a steel cabinet. Signage complying with SS 508 shall be provided to read “ACCESSORIES FOR MOTORISED TROLLEY”. The front part of the cabinet must allow the status of batteries to be easily monitored. The cabinet shall be locked. The key shall be kept in a glass-fronted glazed box alongside the cabinet or as part of the cabinet. Signage complying with SS 508 shall be provided to read “IN CASE OF EMERGENCY, BREAK GLASS FOR KEYS”. A spare key shall be kept in the PSC.

c. Accessibility

Motorised trolley provided at station platform level, mid-tunnel exit staircase and trainway portal shall have access to all trainways. Otherwise, separate motorised trolley shall be provided for each trainway.

d. Siting of trolley at platform level

Motorised trolley provided at station platform level shall be within a travel distance of at most 20m to the end platform steps leading to the trackway.

e. Siting of trolley in mid-tunnel exit staircase

Motorised trolley located in mid-tunnel exit staircase shall not impede the means of escape.

f. Trolley batteries

Two sets of batteries (one spare) shall be provided for each trolley. The trolley with maximum load shall be capable of travelling the distance between stations on one set of fully charged batteries.