Clause 6.2 Dry Rising Main And Hose Reel Systems

6.2.1 Dry rising mains

a. The dry rising main system provided to the station shall be as follows:

(1) Dry rising mains shall be installed in aboveground station where the habitable height is more than 10m.

(2) Every basement level shall be provided with dry rising mains.

(3) Separate dry rising mains shall be provided for the stations and underground trainways.

b. Exception

Aboveground station with all trainways located at external façade and fire engine accessway available alongside the trainways.

6.2.2 Number, location, and size of rising mains

a. Standard

The number, distribution, size, and installation of rising mains shall comply with the requirements stipulated in SS 575.

b. Provision and locations of rising mains

(1) Basement commercial spaces on commercial floors shall be provided with dry rising mains in compliance with SS 575 except as herein modified:

(a) Landing valves shall be provided such that any part within the basement commercial spaces is within 38m (30m hose line length and a jet throw of 8m) from a landing valve, the distance to be measured along a route suitable for the hose line.

(b) Position of landing valves shall be located in the following order of priority:

(i) within fire lift/ smoke-free lobby;

(ii) inside exit staircase; and

(iii) just outside the entrances of the basement commercial spaces.

R Rationale - Clause 6.2.2b.(1)(b)(iii)The rising mains provide ready water supply to firefighters and its landing valve shall be protected against mechanical and fire damage.

(c) Dry rising mains within the basement commercial spaces shall be at least 2-hrs fire-rated.

(2) The design of the dry rising mains in the station shall comply with requirements of SS 575 except as herein modified:

(a) Landing valves shall be provided such that every part of each floor is within 68m (2 x 30m hose line length and a jet throw of 8m) from a landing valve along a route suitable for the hose line.

(b) Lift motor rooms at/ near entrances, under-platform services ducts, cable chambers, electrical rooms, air locks, air plenums, vent shafts, and pedestrian subway/ bridge without commercial activities are exempted from sub-clause (a) above.

(c) Rising mains and the associated landing valves shall be kept free of physical and visual obstruction, and be located:

(i) within fire lift/ smoke-free lobby;

(ii) inside exit staircases; and

(iii) where there is no fire lift lobby, smoke-free lobby or exit staircase, it shall be housed within a protected shaft near to a staircase.

(d) Landing valve, where provided at the station platform public area shall be charged with water when any one of the dry rising mains at the ends of the platform is charged with water.

E(e) Dry rising mains need not be fire-rated. The dry rising mains shall not be routed through smoke exhaust shafts, shops and high hazardous areas.

(f) Each dry rising mains can serve more than two landing valves per floor provided:

(i) There are at least two dry rising mains, one at each end of the station;

(ii) The nominal bore is 150mm with a four-way breeching inlet; and

(iii) The total pressure loss at any landing valve is not more than 4 bars at 38l/s.

(g) Landing valves coverage for tunnel ventilation fan rooms shall be confined to the fans only.

R Rationale - Clause 6.2.2b.(2)(g)In Tunnel Ventilation Fan (TVF) room, the possible hazard is likely the fan motor, though some of these rooms can be very large. Other than the fan motor, the room is devoid of any combustible and fire hazard. As such, the coverage of landing valve, hose reel and detector need only be confined to the fan and not the entire room. This is also in cognizance that the TVF room is part of the emergency ventilation air plenum, which shall always be a restricted area. No storage, other usage and activity shall be allowed in the room.

(h) Access to landing valves shall not be obstructed by vehicle parking, furniture, equipment, or other materials. Where landing valve is located near to a doorway, the swing path of the door (including any grille gate/ door which could possibly be installed in the future) shall not encroach onto the swing paths of the landing valve cabinet/ protected shaft door. The swing path of grille gate/ door of units, whether to be installed or not, shall be annotated on plans. In the case where the grille gate/ door, when installed, will encroach onto more than half the width of the corridor, the QP shall annotate on the building plans that such installation is not permitted.

c. Standby fire hoses

Standby fire hose shall be provided in accordance with Cl.6.2.4. Two standby fire hoses shall be provided at each of the landing valves, but one standby fire hose is also acceptable if coverage is adequate.

6.2.3 Breeching inlets

a. All stations fitted with rising mains shall have a fire engine accessway/ fire engine access road for firefighting appliances within 18m of the breeching inlet. Where the breeching inlets are located at the vent shafts, the design shall be such that the firefighting operation near the breeching inlets is not affected by smoke exhausting from the vent shafts. The breeching inlets shall be visible from the fire engine accessways/ fire engine access roads.

b. The requirements and provisions for breeching inlets for the rising main system shall be in accordance with the SS 575. Connecting pipes between the inlets and the vertical run of the rising mains, where applicable, shall be kept as short as possible.

c. The metal box for the breeching inlet need not be provided if the inlet is installed in recesses and protected from mechanical damages. A glass-fronted cover/ door complying with the requirements of SS 575 shall be provided.

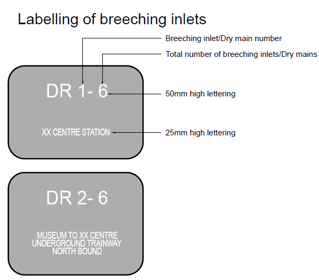

d. Breeching inlets shall be appropriately numbered and labelled as shown in Diagram 6.2.3. The total number of dry rising mains provided for the station (including tunnels) shall be indicated. The wording shall be white on a contrasting background.

Diagram 6.2.3: Labelling of Breeching Inlets

6.2.4 Standby fire hose for rising mains

Standby fire hoses shall be provided for every rising main. The following requirements shall be complied with:

a. Type and folding method

(1) The standby fire hose shall be of 63.5mm nominal internal diameter in order to ensure that the hose coupling will fit the existing coupling tail pieces. The hose shall be rugged and capable of carrying water under substantive pressure in accordance with BS 6391. The fire hose shall be of Type 3 as stipulated in BS 6391.

(2) The fire hose couplings shall be manufactured to BS specifications or equivalent and of be light alloy or gunmetal. The coupling shall be of 63.5mm diameter and be of the instantaneous type with standard (double-pull) release mechanism. The couplings shall be secured to the hoses with galvanised mild steel wire and applied over a hose guard of synthetic fibre. It shall be able to withstand a minimum working pressure of 15 bars.

(3) Each hose shall have a standard length of 30m and shall be kept stowed in a Dutch Roll and housed in a glass fronted cabinet. The Dutch Roll shall be rolled in the manner shown in Diagram 6.2.4c.(9).

b. Position

(1) The fire hose shall be installed just next to, but not more than 2m from the landing valve as shown in Diagram 6.2.4c.(7).

(2) The entire fire hose and cabinet shall be installed away from direct sunlight.

c. Mounting

The wall mounted fire hose and cabinet shall be as follows:

(1) The cabinet shall be firmly mounted on the wall and able to withstand the weight of the hose(s) it houses.

(2) The cabinet shall be constructed of non-combustible material and be maintenance free.

(3) The cabinet lock, if provided, shall be one that can be operated manually from the inside without the use of a key when the front tempered glass (minimum 300mm x 300mm) is broken by firefighters.

(4) The cabinet swing door shall be made openable such that it will not obstruct the retrieving of the fire hose by firefighters.

(5) The depth of the cabinet shall not exceed 250mm for one fire hose or 350mm for two fire hoses.

(6) The cabinet shall be painted in a contrasting colour such that it is conspicuous and easily identified.

(7) The wording, “FIRE HOSE”, with letter height of at least 50mm and shown in contrasting colour, shall be painted directly on the front panel as shown in Diagram 6.2.4c.(7).

(8) In lieu of the cabinet, a simple wall mounted cradle for the fire hose can be provided, but only in the riser main shaft. The cradle shall be constructed and positioned to facilitate the retrieving of fire hose by firefighters.

(9) The cradle (in lieu of the cabinet) shall be maintenance-free. The fire hose installation height shall be limited as indicated in Diagram 6.2.4c.(9).

d. General

(1) Only clean, dry and compactly rolled (Dutch Roll with the Velcro strap secured as shown in the Diagram 6.2.4c.(7) and Diagram 6.2.4c.(9)) hose(s) shall be placed in the cabinet.

(2) BS 6391 stipulates the technical requirements for quality acceptance standards of the fire hose. In addition, the abovementioned requirements shall be applicable for acceptance of the standby fire hose.

(3) Spare hoses

Two lengths of spare fire hoses shall be kept in stock and ready for replacement.

6.2.5 Hose reels

a. Provision

(1) Hydraulic hose reel(s) conforming to the requirements in SS 575 shall be provided throughout the stations including the commercial spaces and underground links leading to the underground station entrances except:

R Rationale - Clause 6.2.5a.(1)Hose reel shall not be provided at train platform because any hose reel water that is discharged acts as a good conductor of electrical currents when in contact with high voltage electrical apparatus, to cause electrocution to the person operating the hose reel.

(a) buffer areas (including plant rooms within these areas), station platforms and outdoor cooling tower area;

(b) ground level entrances with no rooms/ kiosk/ ATM;

(c) cable chambers and under-platform services ducts;

(d) air shafts;

(e) standalone bin centres;

(f) roof level of single storey stations/ buildings with roof height not more than 12m or inaccessible pitched roof up to 24m from grade level used solely for roof-mounted PV installations in accordance with Code of Practice for Fire Precautions in Buildings;

E(g) roof level of an external/ open-sided overhead bridge/ shed/ linkway/ walkway with clear width less than 6m, roof height not more than 12m and used solely for roof-mounted PV installations in accordance with Code of Practice for Fire Precautions in Buildings; and

(h) green roofs which are accessible for maintenance purposes only and which comply with Cl.10.2.1b.(1)(a) of the Fire Code.

(2) Hose reels coverage for tunnel ventilation fan rooms shall be confined to the fans only.

R Rationale - Clause 6.2.5a.(2)In Tunnel Ventilation Fan (TVF) room, the possible hazard is likely the fan motor, though some of these rooms can be very large. Other than the fan motor, the room is devoid of any combustible and fire hazard. As such, the coverage of landing valve, hose reel and detector need only be confined to the fan and not the entire room. This is also in cognizance that the TVF room is part of the emergency ventilation air plenum, which shall always be a restricted area. No storage, other usage and activity shall be allowed in the room.

b. Size and type

The hose shall be of 20mm or 25mm nominal diameter and conform to EN 694, shall not exceed 30m in length and terminate in “shut-off” branches with 4mm or 6mm nozzles.

c. Siting and installation

(1) Siting and details of installation for hose reels shall comply with the requirements in SS 575.

(2) Hose reels shall be sited in prominent and accessible locations within a distance of 5m from the exit door but not inside exit staircases. If there are parts of the floor space that are beyond the 36m coverage (30m hose path and 6m throw) of the hose reel, additional hose reels shall be provided at the common area or at a distance of not more than 5m from the exit access door of a room.

R Rationale - Clause 6.2.5c.(2)The proximity of 5m serves to clarify the acceptable location between hose reel and exit access door or exit door.

(3) Hose reels located within a room shall not be used for covering the areas outside the room.

(4) Where the hose reel and automatic sprinkler systems share the same water tank, the hose reel tap-off points shall be above the sprinkler system’s reserve capacity.

R Rationale - Clause 6.2.5c.(4)This is to prevent the draw-off water of the hose reel system from affecting the effective capacity required for the sprinkler system.

d. Piping

The use of copper or stainless steel piping is permissible for the connection of the hose reels to the PUB mains.

) or https:// as an added precaution. Share sensitive

information only on official, secure websites.

) or https:// as an added precaution. Share sensitive

information only on official, secure websites.

(d)-new.png?sfvrsn=569671ad_3)

(f).png?sfvrsn=7190f55e_2)