Clause 7.1 Air-Conditioning And Mechanical Ventilation Systems

7.1.1 General

Where an air-conditioning system is provided in lieu of a mechanical ventilation system for emergencies, all the requirements specified in this Code for mechanical ventilation systems shall apply to the air-conditioning system.

7.1.2 Construction of ductwork

Ducts for air-conditioning and mechanical ventilation systems shall be constructed in compliance with all the following requirements:

a. Materials

Air-conditioning or other ventilation ducts, including framing thereof, shall be constructed of steel, aluminium, glass fibre batt, mineral wool batt, or other approved materials.

b. Support

Air-conditioning or other ventilation ducts shall be adequately supported.

c. Duct coverings, duct linings, and flexible connection

Duct covering, duct linings, and flexible connection shall be non-combustible. However, if it is necessary to use combustible material, it shall:

(1) when tested in accordance with methods specified in this Code, have a surface flame spread rating of not lower than Class 0;

(2) when involved in fire, generate a minimum amount of smoke and toxic gases; and

(3) be at least 1m away from a fire damper.

d. Flexible joints and connections

(1) Flexible connections at the ends of ventilation ductwork connecting terminal units, extract units, and ventilation grilles shall not exceed 4m.

(2) Flexible joints, which are normally provided to prevent and/ or allow for thermal movements in the duct system, shall not exceed 250mm in length.

(3) Flexible joints shall be made of material classified as ‘not easily ignitable’ when tested under BS 476: Part 5.

e. Duct Enclosure

Enclosure of ducts shall comply with the requirements in Cl.3.8.9a..

f. Ductwork through smoke-free or fire lift lobbies

Ventilation ducts shall not pass-through smoke-free or fire lift lobbies. Where unavoidable, the part of the ventilation duct within the lobby shall be enclosed in masonry construction with fire resistance rating at least equal to that of the elements of structure. If other forms of fire resisting construction are used, a fire damper shall be fitted where the duct penetrates the lobby enclosure.

g. Ductwork through separating walls

No air-conditioning or ventilation duct shall penetrate separating walls.

h. Fire-rated duct

(1) Where proprietary fire-rated materials are used to construct the fire-rated duct, the fire rating of the fire-rated duct shall have the same period of fire resistance as the wall or floor it penetrates.

(2) Proprietary fire-rated duct shall be tested to BS 476: Part 24 or equivalent and its usage be approved by the SCDF.

(3) Running of non-fire-rated duct and/ or other station services above the proprietary fire-rated duct shall be avoided. When unavoidable due to physical constraints, the supports to such non-fire-rated duct and/ or other station services running above the proprietary fire-rated duct shall be strengthened, such that the tensile stress generated on the supports shall not exceed 10N/mm2. The non-fire-rated duct and/ or station services shall also be adequately protected to prevent collapse in a fire which will otherwise affect the stability of the proprietary fire rated duct below.

(4) Fans forming part of a fire-rated duct shall also be enclosed in the same fire-rated enclosure.

i. Control panel

R Rationale - Clause 7.1.2i.The control panel serving the fans of smoke control systems are crucial and must not be located within any smoke layer to ensure that the integrity of the smoke control system is not compromised in a fire emergency. The exhaust systems would not be operable in the event of failure of the control panels.

The location and placement of control panels serving engineered smoke control and smoke purging systems shall be located next to the main alarm panel or in rooms with at least 1 hr fire resistance. The control panels shall be clearly visible, readily accessible for operation and maintenance, and mounted at a height not more than 1.8m from the finished floor level.

7.1.3 Insulation of pipework

Insulation for pipework associated with the air-conditioning and mechanical ventilation systems shall comply with the following requirements:

a. Flame spread rating

Insulation material for pipework, together with vapour barrier lining and adhesives shall when tested in accordance with the methods specified in this Code, have a surface flame spread of not lower than Class 0.

b. Plastic and foam rubber insulation

Notwithstanding the requirements of Cl.7.1.3a., the use of plastic and foam rubber insulation materials of a lower classification is permitted only in aboveground stations if:

(1) it is of the self-extinguishing type; and

(2) the insulation is covered by or encased in a metal sheath, hybrid plaster, other non-combustible cladding material, or a fire-rated proprietary pipework system tested in the manner acceptable to the SCDF, provided that any opening in the element of structure or other part of a station penetrated by the pipework shall be effectively fire-stopped by replacement of the insulation material at the junction of penetration with fire resistant material having equal fire resistance rating.

7.1.4 Air plenum

Air plenums which do not contain combustible materials need not be provided with fire protection.

7.1.5 Fire Dampers

Any fire damper shall have a fire resisting rating of not less than that required for the compartment wall or compartment floor through which the relevant section of the ventilation duct passes. Fire dampers shall be of the type approved by the SCDF and constructed in accordance with the requirements in SS 333.

a. Provision of fire dampers

Ventilation ducts which pass directly through a compartment wall or compartment floor shall comply with the following:

(1) where the ventilation duct does not form a protected shaft or is not contained within protecting structure, the duct shall be fitted with a fire damper where it passes through the compartment wall or compartment floor; and

(2) where the ventilation duct forms a protected shaft or is contained within a protecting structure, the duct shall be fitted with fire dampers at the shaft inlets and outlets.

b. Installation of fire dampers

(1) Fire dampers shall be installed so that the casing completely penetrates through the compartment wall or floor, and the casing shall be retained, either:

(a) on both sides by means of flanges in such a manner that it can expand under fire conditions without distorting the blades in the closed position, or

(b) on the accessible side by means of one flange only, which can be fixed to the damper and to the wall through slotted holes to allow for expansion.

(2) Flanges shall be butted against the face of the compartment wall or floor and fixed to the damper casing.

(3) Ductwork connected to the damper shall be attached in such a manner as to ensure that the damper remains securely in position and is fully functional in the event of damage of ductwork.

(4) The clearance between the damper body and the sides of the penetration shall not be less than that of the tested prototype and be not greater than half the width of the angled section of the collar.

(5) The space between the damper body and the opening in the wall or floor shall be fire-stopped.

(6) Vertically positioned fire dampers shall be installed in such a manner that the direction of air flow assists in the closure of the damper.

(7) Connections to fire dampers

The distance between the plane through a closed fire damper and ducting, flexible connections, duct coverings, internal linings, and the like, shall be:

(a) no less than 1m when such parts are made of materials with fusing temperatures less than 1000ºC;

(b) no less than three times the diagonal or diameter of the damper; and

(c) no less than 2m when such parts are made of materials that are combustible, except for vapour barrier to provide thermal insulation.

(8) Fire damper inspection access doors

Each fire damper installation shall be provided with an inspection access door in the ventilation duct, either upstream or downstream, as appropriate. The access door dimension shall measure 450mm (L) x 450mm (W); for smaller ducts, the door width dimension can be reduced to the width or depth of the duct. Access doors shall be hinged and fitted with sash locks and be constructed of minimum 1.25mm suitably braced sheet steel. Openings in ducts shall be stiffened by a sheet steel frame.

c. Prohibition of fire dampers

Fire dampers shall not be fitted in any of the following locations:

(1) openings for ducts of emergency ventilation systems in walls of ventilation shaft, or

(2) openings in walls of a protected shaft when the openings have a kitchen exhaust duct passing through it, or

(3) opening in walls of a protected shaft when the openings have a fume hood exhaust duct passing through it, or

(4) anywhere in an air pressurising system, or

(5) in locations explicitly prohibited in this Code.

7.1.6 Locations of intakes and return air openings

a. Openings for the intakes of outdoor air to all air handling systems, mechanical ventilation systems, pressurisation systems of exit staircases and internal corridors, and smoke control systems shall be no less than 5m from any exhaust discharge openings.

b. All return air openings and outdoor air intakes shall be located and arranged such that sources of ignition, such as lighted matches and cigarette butts, which accidentally enter the openings and intakes cannot be deposited onto the filter media.

c. Re-circulation of smoke

The intake and exhaust air shafts shall be positioned or protected to prevent re-circulation of smoke into the system through air intake openings, station entrances, and other surface of openings. Adjacent structures and property shall also be considered.

7.1.7 Air handling unit (AHU) room

Rooms having no other usage than housing air handling equipment or package units and their associated electrical controls are not regarded as areas of high risk.

a. Compartmentation

R Rationale - Clause 7.1.7a.Rooms having no usage other than housing air handling equipment or package units, and their associated electrical controls are typically not regarded as areas of high risk and therefore compartmentation is not required. However, fire dampers shall be provided within the air ducts of the air handling equipment where they penetrate through compartments to prevent fire spread.

(1) Where the air handling equipment serves more than one compartment, fire dampers shall be provided in air ducts at penetrations through the compartment walls and floors to comply with the requirements in Cl.7.1.5.

(2) Where AHU rooms are vertically stacked, each AHU room shall be separated by a compartment floor at every level.

b. Smoke Detectors

(1) Smoke detectors of approved type shall be incorporated in the return air stream immediately adjacent to:

(a) AHUs serving more than one storey or compartment, or

(b) a single AHU in excess of 15000m³/h.

(2) The function of smoke detectors, where required by this Code, is to initiate action to shut down the AHU automatically when the smoke density in the return air system has become unacceptable for recycling.

c. Stop switch

Where the AHUs in a station are not centrally controlled, each AHU exceeding 8500m³/h shall be provided with a manual stop switch to facilitate quick shutting down of the fan in the case of fire. For ease of access, this switch shall be located on the wall next to the door opening of the air handling equipment room.

7.1.8 Ventilation system for exit staircase and internal exit passageway

A mechanical ventilation system for each exit staircase and internal exit passageway, if provided, shall be an independent system of supply mode exclusive to the particular staircase, or internal exit passageway, and it shall comply with all of the following requirements:

a. Supply air for the system shall be drawn directly from the external space/ air shaft, with intake point not less than 5m from any exhaust discharge openings.

b. For exit staircase serving more than four storeys, supply air shall be conveyed via a vertical duct extending throughout the staircase height and discharging through outlets distributed at alternate floors.

c. Where the supply air duct serving the exit staircase must penetrate the staircase enclosure, the portion of the duct where it traverse outside the staircase shall be enclosed in masonry construction or drywall complying with Cl.3.8.7c. of at least the same fire resistance as the elements of structure, and it shall not be fitted with fire dampers.

d. The ventilation system shall be of supply mode only, and of not less than 4 air changes per hour.

e. The mechanical ventilation system shall be automatically activated by the station fire alarm system. In addition, a remote manual start-stop switch shall be made available to firefighters at the FCC, or, where there is no FCC, next to the main fire alarm panel.

f. Visual indication of the operational status of the mechanical ventilation system shall be provided.

g. The mechanical ventilation for the exit staircase shall be maintained at higher pressure with respect to the mechanical ventilation system of the adjacent fire lift lobby.

h. Where duct risers are required to be enclosed in protected shafts, the protected shafts shall be enclosed in masonry construction or drywall complying with Cl.3.8.7c..

7.1.9 Ventilation system for smoke-free lobby and fire lift lobby

a. The ventilation system shall be of supply mode only of not less than 10 air changes per hour.

b. Supply air shall be drawn directly from the external space/ air shaft with intake point not less than 5m from any exhaust discharge or openings for natural ventilation.

c. Any part of the supply duct running outside the smoke-free or fire lift lobby which it serves shall either be enclosed or constructed to give a 1-hr fire resistance rating. The SCDF may, at its discretion, require a higher fire resistance rating if the duct passes through an area of high fire risk.

d. The mechanical ventilation system shall be automatically activated by the station fire alarm system. In addition, a remote manual start-stop switch shall be made available to firefighters at the FCC or where there is no FCC, next to the main fire alarm panel.

e. Visual indication of the operational status of the mechanical ventilation system shall be provided.

7.1.10 Ventilation system for fire pump room and generator room

Where mechanical ventilation is installed to provide a smoke-free environment for the room housing the fire pump or emergency generator, such systems shall be independent of each other and of any other system serving other parts of the station/ building, and shall comply with all of the following requirements:

a. Supply air shall be drawn directly from the external space/ air shaft and its intake point shall not be less than 5m from any exhaust discharge openings. Exhaust discharge shall also be direct to the external space/ air shaft.

b. Where the corresponding ducts run outside the room, they shall either be enclosed in a structure or be constructed to give at least the same fire rating as the room which they serve, or that of the room through which they traverse, whichever is higher. The rating shall apply to fire exposure from both interior and exterior of the duct or structure. Where the duct risers are required to be enclosed in a protected shaft constructed of masonry or drywall complying with Cl.3.8.7c., they shall be compartmented from the rest of the shaft space containing other ducts or service installations.

c. No fire damper shall be fitted in either supply or exhaust duct required under this clause.

d. A duct serving areas other than rooms housing equipment stated in this clause shall not pass through such rooms.

7.1.11 Ventilation system for Fire Command Centre (FCC)

The FCC can either be air-conditioned, naturally ventilated, or mechanically ventilated. The air-conditioning or mechanical ventilation shall be independent of each other and any other system serving other parts of the station. Where mechanical ventilation is required, it shall also comply with all the following requirements:

a. Supply air shall be drawn directly from the external space/ air shaft and its intake point shall not be less than 5m from any exhaust discharge openings. Exhaust discharge shall also be direct to the external space/ air shaft.

b. Where the corresponding ducts run outside the FCC, they shall either be enclosed in a structure or be constructed to give at least the same fire rating as the room which they serve or that of the room through which they traverse, whichever is higher. Where the duct risers are required to be enclosed in a protected shaft constructed of masonry or drywall complying with Cl.3.8.7c., they shall be compartmented from the rest of the shaft space containing other ducts or service installations.

c. No fire damper shall be fitted in either supply or exhaust duct required under this Clause.

d. A duct serving areas other than the FCC shall not pass through the room.

7.1.12 Exhaust system for kitchen

a. Provision

A mechanical exhaust system for the cooking area of a kitchen in an eating establishment or the like shall be independent of those serving other parts of the station. It shall also comply with all the following requirements:

(1) The hood and ducts for the exhaust shall have a clearance of 500mm from unprotected combustible materials.

(2) The exhaust shall discharge directly to the external space/ air shaft and shall not be less than 5m from any air intake openings.

(3) The exhaust duct, where it runs outside the kitchen, shall either be enclosed in a structure or be constructed to give at least the same fire rating as the kitchen or that of the room through which it traverses, whichever is higher. The rating shall apply to fire exposure from both interior and exterior of the duct or structure. Where the duct riser is required to be enclosed in a protected shaft constructed of masonry or drywall complying with Cl.3.8.7c., it shall be compartmented from the rest of the shaft space containing other ducts or services installations.

(4) No fire damper shall be fitted in kitchen exhaust ducts.

b. Sharing of kitchen exhaust system

Sharing of kitchen exhaust system for food and beverage outlets is allowed, provided all the following conditions are complied with:

(1) For food courts

(a) The food court shall be under a single ownership/ operator.

(b) All kitchen exhaust ducts running outside the food court shall have 1-hr fire resistance rating or shall not be less than that for the elements of structure, whichever is higher.

(2) For restaurants/ small F&B outlets (e.g. snack bars, food kiosks, etc.)

(a) Restaurants and small F&B outlets that are sharing the same kitchen exhaust system shall be located on the same storey and within the aggregate zone area not exceeding 2000m2. The maximum length of the aggregate zone covering from the first to the last restaurant/ F&B outlet shall not exceed 50m.

(b) The aggregate floor area of the restaurants and F&B outlets shall not exceed 1000m2.

(c) Common ducts shall be provided with a common exhaust fan.

(d) The station shall be protected by an automatic fire sprinkler system.

(e) The exhaust hood shall be fitted with a wet chemical fire extinguishing system.

(f) The fire rating of the common kitchen exhaust duct running outside the restaurants shall have 1-hr fire resistance rating or shall not be less than that for the elements of structure, whichever is higher.

(Note: Kitchen exhaust ducts include both horizontal and vertical ducts.)

c. Kitchen exhaust duct

(1) A kitchen exhaust duct running outside a station shall not be located within 3m of any unprotected openings. This separation distance can be reduced to 1.5m if the unprotected opening is on the same plane as the duct. See Diagram 7.1.12c.(1) - 1 and 2.

(2) Where the distances mentioned above cannot be achieved, a fire resistant construction having at least ½ hr fire resistance shall be placed between the duct and the unprotected opening. See Diagram 7.1.12c.(2).

(3) A non-fire-rated kitchen exhaust duct shall not be located above an LPG storage cabinet unless they are separated from LPG cylinders by a minimum of 2-hr fire-rated masonry construction above and beside the cylinders. See Diagram 7.1.12c.(3).

(4) The kitchen exhaust duct shall be located at least 3m from any unprotected LPG cylinders. Non-fire-rated kitchen exhaust duct shall be located at least 600mm from the vapouriser or any liquid-phase LPG pipeline. See Diagram 7.1.12c.(4).

d. Maintenance

! Note to QPs on Clause 7.1.12d.The respective building owner, MCST and eating outlet operators shall ensure that the entire(interior and exterior) kitchen exhaust duct and kitchen hood shall be degreased and cleaned at least once every 12 months. The work shall be carried out by a specialist and the records of cleaning and degreasing shall be kept by the owner/operator for verification.

All kitchen exhaust systems shall be properly maintained. The entire (interior and exterior) exhaust duct and kitchen hood shall be degreased and cleaned at least once every 12 months. The work shall be carried out by a specialist and the records of cleaning and degreasing shall be kept by the owner/ operator for verification. This requirement shall be included in the Fire Safety Instruction Manual.

Rooms housing batteries shall comply with the following requirements:

a. The batteries shall be of either vented or sealed type.

b. The room ventilation system shall be designed to limit the maximum concentration of Hydrogen (H2) gas to 1% of the total volume of the room during the worst-case event of simultaneous “boost” charging of the batteries. The inlets and outlets of the ventilation system shall be properly located so that there is no stagnant area in the room.

c. Adequate hydrogen gas detectors shall be provided inside the room to monitor the hydrogen concentration and to activate the fan, if necessary, to ensure that the hydrogen concentration level at any part of the room does not exceed 1% of the total volume of the room. Display panels showing the readings of the detectors shall be located at the entrance to the room. At the same time, an alarm signal shall be sent to a manned station such as PSC, guard house or FCC.

d. The design of the battery room ventilation shall be in accordance with BS EN IEC 62485-2 & BS EN IEC 62485-3.

e. For mechanically ventilated battery rooms, the ventilation requirement shall be based on Cl.7.1.13d., or 6 air changes per hour, whichever is higher.

f. No fire damper shall be provided in the essential ventilation system and ducts passing through other compartments shall have 2-hr fire resistance rating.

g. Essential fans and associated electrical controls shall be backed up with a secondary source of power supply.

E7.1.14 Smoke control fan rooms

Ductwork not serving smoke control fan rooms shall not pass through the smoke control fan room.

7.1.15 PVC pipes

PVC pipes are prohibited in underground stations, except PVC pipe sleeves and condensate drain pipes for air-conditioning units as stipulated in Cl.3.15.13.

7.1.16 Air shafts

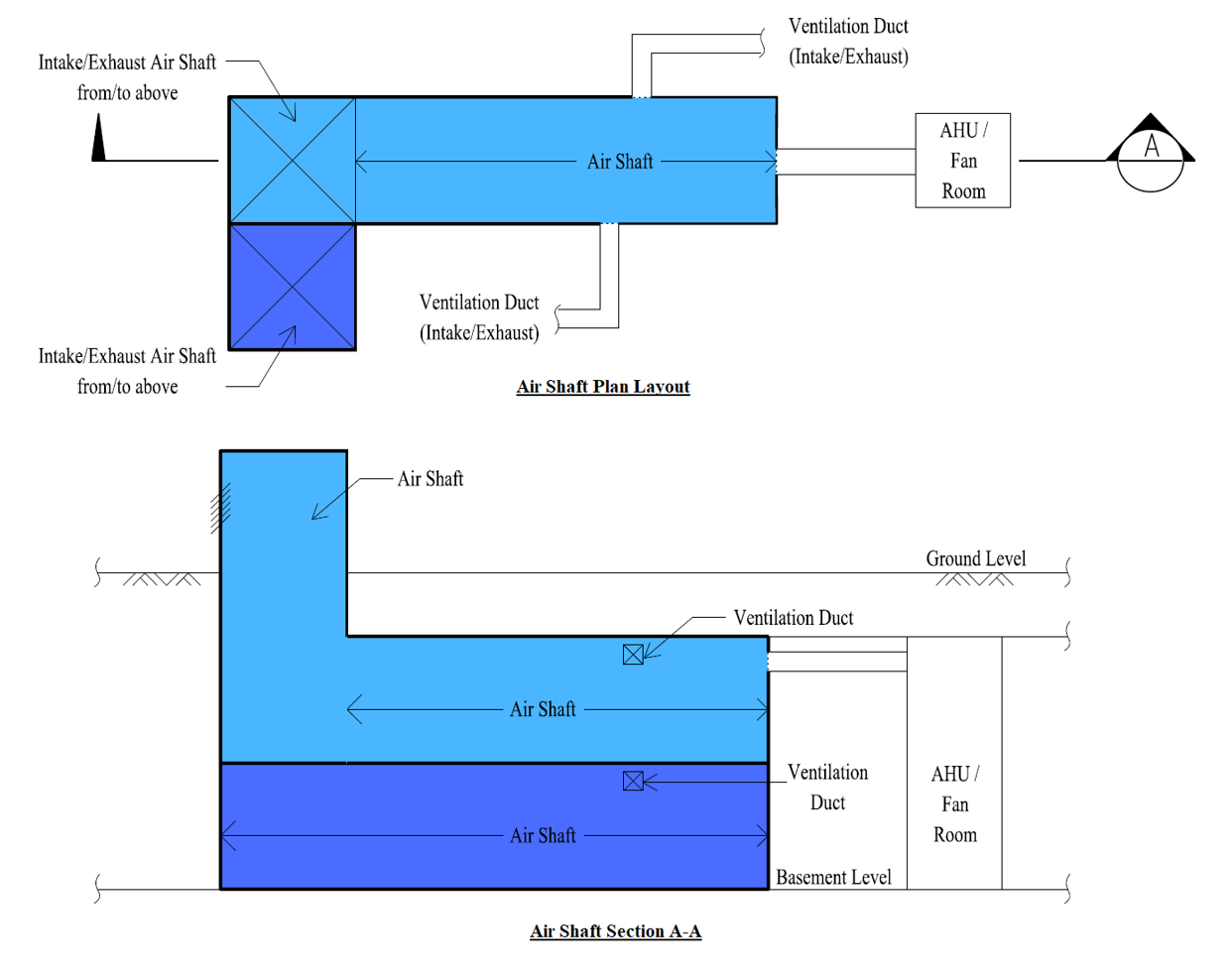

a. Fresh/ exhaust air of the station’s smoke control and mechanical ventilation systems can be taken from/ discharge to the intake/ exhaust air shafts as shaded in Diagram 7.1.16 – 1 & 2 below respectively of the underground station. The connection to the air shafts shall be designed to prevent recirculation of air to the other ventilation system.

Eb. Air shafts shall be constructed of masonry and shall only contain equipment and services serving the air shafts and services stated in Table 7.1.16.

7.1.17 Power supply

Primary and secondary power supply shall comply with Cl.5.2.

7.1.18 Replacement air

Where replacement air is taken from doorways at station entrances, devices or other measures shall be incorporated to admit replacement air upon activation of the emergency ventilation system. This is to achieve the design requirements during operating hours and non-operating hours when the station is closed for passenger service.

) or https:// as an added precaution. Share sensitive

information only on official, secure websites.

) or https:// as an added precaution. Share sensitive

information only on official, secure websites.